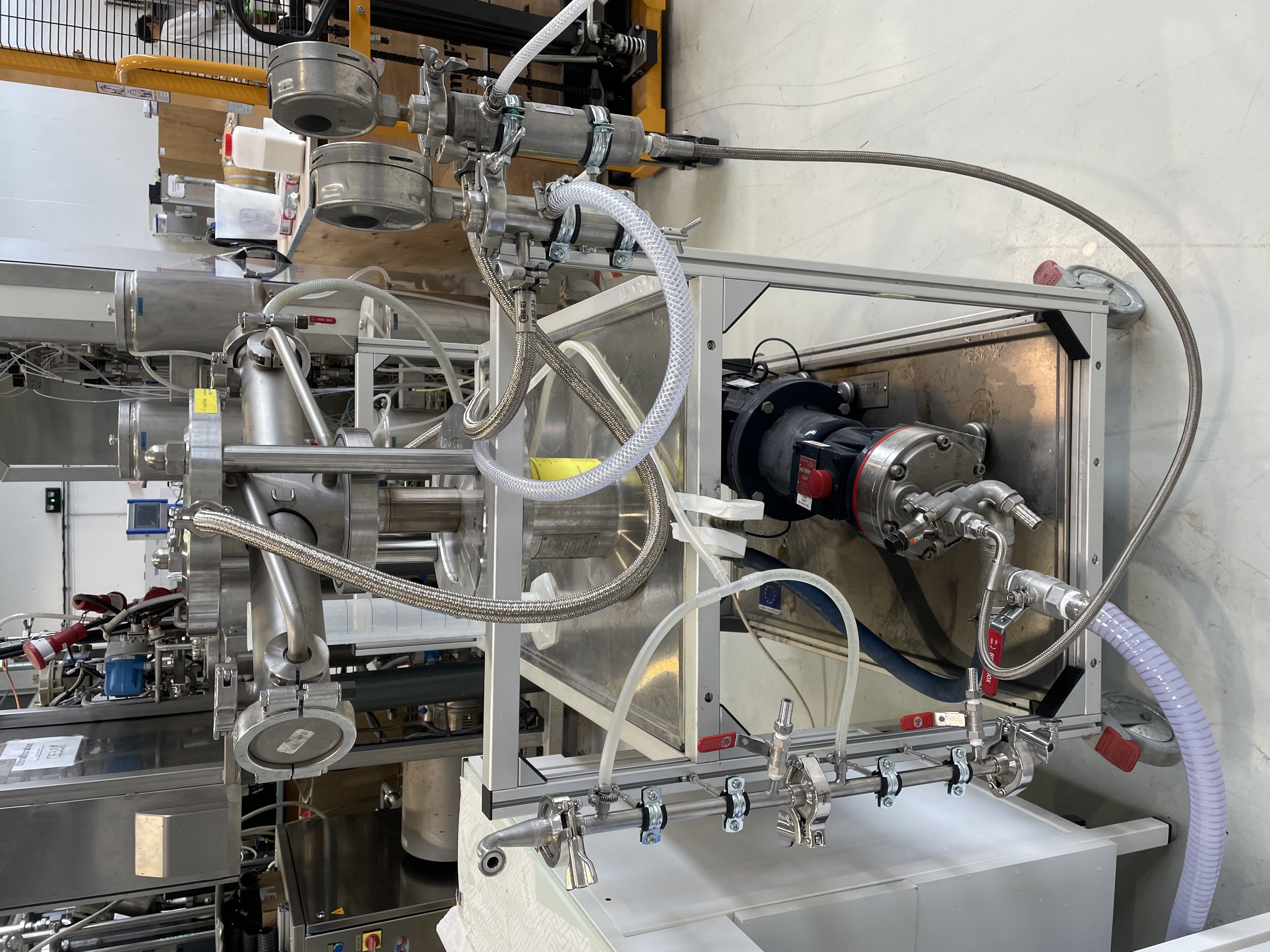

Pilot plant plateform

A link to secure the transfer of innovation to industry

La Chaire de Biotechnologie assure le transfert de la recherche vers l’industrie grâce à sa plateforme d’usine pilote modulaire. Cette usine pilote se compose d’un parc d’équipements pilotes de laboratoire, déployés au sein d'une halle technologique, et recouvre l’ensemble de la chaine de valeur de la bioraffinerie, de la production à la purification. Elle est notamment orientée vers les bioprocédés et les techniques séparatives. Avec la capacité d’évaluer la faisabilité et les performances de procédés au stade pilote, la plateforme permet une première étape de scale-up, créant ainsi une continuité entre recherche et développement technologique.

Contact

Fanny Duval

fanny.duval@centralesupelec.fr

Our equipements

- 20 L instrumented bioreactor (GPC Bio, Global Process Concept) - Culture of microorganisms

- 30 L instrumented raceway - Culture of microalgaes in open pond system

- 100 L Membrane Bioreactor (Seprosys) - Culture of microorganisms with continuous clarification

- Ultracentrifuge equipped with 2 rotors: fixed (70000 rpm, 450000 x g) and swing (32000 rpm, 175000 x g) (Optima XPN-80, Beckman Coulter) - Separation of cellular constituents

- Centrifuge with 2 rotors : one with a capacity of 6 L (8000 rpm, 15970 x g) and one allowing semi-continuous centrifugation (2000 rpm, 39900 x g) (Avanti J-26S XPI, Beckman Coulter) - Microalgae harvesting or product clarification

- Ultrasound pilot with a 1000 W 20 KHz 230 V Sonotrode (Hielscher UIP1000Hdt-230) - Ultrasound assisted extraction

- Conventional electrodialysis pilot with 2 compartments (Eurodia EUR2CP) - Salt content reduction

- Bipolar electrodialysis pilot with 3 compartments (Eurodia EUR2CP) - Production of acids and bases from salts

- 2L Tangential flow filtration pilot (Armfield FT-17) - UF, MF, NF and IO: Ceramic Membranes of 56.3 cm² and Organic Membranes of 63.6 cm². Tests with Small Volumes

- 8L Tangential flow filtration pilot UF, MF, NF and IO (Alfalaval TestUnit M20) - Membrane Screening or Small-Scale Tests :

- Flat organic membranes with a surface area of 0.036 m² on stackable discs, reaching a total working surface of 0.72 m²

- Spiral organic membranes with a surface area of 0.6 m²

- Single-Channel ceramic membrane with a surface area of 50 cm²

- Micro- and ultrafiltration pilot with ceramics membranes (TIA SKID-14EO35) - Retention of macromolecules, separations

- Nanofiltration and inverse osmosis pilote with spiral organic membranes (TIA 14EO35) - End-process product concentration, demineralization

- Preparative chromatography pilot SMS (Seprosys SSMB6-9ECP) - Continuous separation of organic acids and sugars

- Gas-liquid absorption pilot assisted by membrane contactors - Biomethane or syngas purification

Examples of applications

- Purification of pentoses from hemicellulose hydrolysate by membrane filtration and ion exchange with sulfuric acid recycling by electrodialysis

- Purification of organic sugars and acids by simulated moving bed chromatography SMB

- Purification of biomethane from an agricultural methanizer by gas-liquid absorption with dense tubular membrane contactor technology

- Study of the treatment of an agricultural effluent thanks to the culture of microalgae in "Raceway".

- Study on biological methanation in instrumented MBR